BollardScan. The smartest solution for testing bollards.

The increase in international trade and the growing popularity of cruises have caused an increase in both shipping density and the size of vessels. This has resulted in an increased level of activity in ports and harbours, but also in an increase level of safety risks, particularly during mooring and un-mooring operations.

The state of the mooring bollards is often unknown.. The bollards are expected to withstand larger forces, but the construction and the anchoring are often worn out and no longer has the capacity to meet with increased forces. The lack of dedicated regular maintenance may result in serious damage to vessels and quayside walls and fatal accidents cannot be ruled out.

Why Test Bollards

• Recent accidents have caused huge financial claims

• Lack of information on use of bollards

• Bollards are the last link in the mooring chain and are an often neglected asset (both shore and vessel)

• Estimated 80% of bollards are over 60 years old (conservative estimate)

• Knowledge of the bollard and its anchoring contribute to safe mooring operations

• Information on bollards status means financial gain

WHO ARE WE?

• We are specialized in non-destructive testing of bollards in ports, harbours and inland waterways

• An international team with over 60 years of experience in the maritime industry with a hands on mentality

• In collaboration with science institutes we deliver a highly reliable, scientifically underpinned way of testing marine bollards in a non-destructive way

WHAT CAN WE DO FOR YOU?

• Rapid assessment on the condition of bollards and their foundations

• Assist in predictive maintenance schedule’s on quayside and bollards

• Assist in surveying a variety of structures, i.e. bollards, piers and quays can be monitored

• Cost effective operations

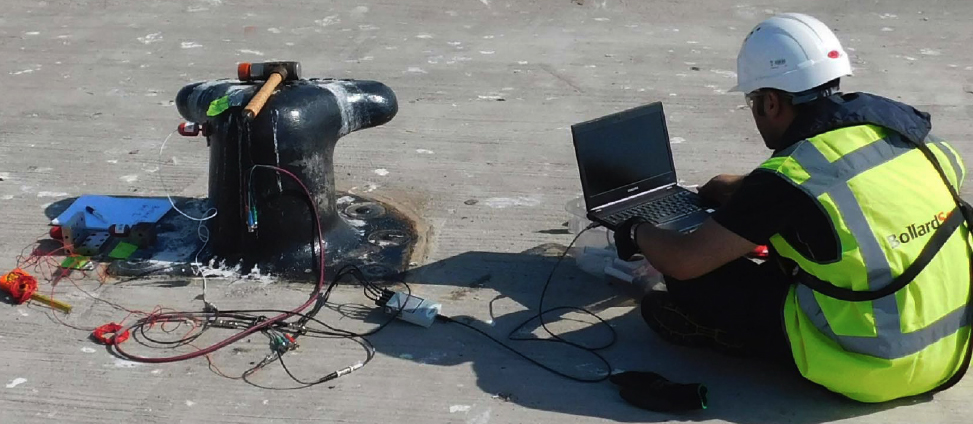

• Lightweight mobile equipment allows for measuring in any surrounding

• Determine a recommended working load

• Nonintrusive load monitoring

CDMS Sub Surface Engineering Limited

Our diverse and experienced teams of Commercial Divers enables CDMS Sub-Surface Engineering Limited

to offer its customers a complete and cost-effective solution to Civil and Marine projects

within the Civil Engineering Industry.

A non-destructive way of testing

BollardScan is a non-destructive way of testing and will be executed by our well-trained staff who are highly experienced inport operations. The equipment is portable and lightweight and can be used even in the most remote parts of any port.

Safety is the name of the game

The safety of man and environment has been tantamount to the development of the BollardScan. The risks of accidents and incidents during mooring operations are likely to increase rather than decrease. The load testing of bollards with tugboats, heavy wires and other machinery belong to the past now that BollardScan is available.

Structural Damage

Structural Damage along the water course is generally more severe at water level we find salt, a mild acid, lowers the pH in the concrete. The acidic reaction attacks the concrete paste and aggregate, increasing the pore size and allowing additional water and chemicals into the concrete which can exacerbate the freeze/thaw cycle damage.